Ready Pour

Ready Pour

2012

I didn't like using the laundry detergent caps for measuring out the detergent because then it would get all over the container, or your hands, or the counter, later. The idea here is to design a container with a handle that can measure the amount of detergent you need. Then you can drain that directly into your washing machine basin. Designed and CAD'd it. Friend of a friend 3D printed it for me. And I did my best to draw up a provisional patent for it.

Tried submitting it to some "product design/idea" portals/competitions, like I think P&G had one, Quirky maybe, and maybe a couple others. They didn't go anywhere, and not long after, detergent pods came out! These were a way better solution, and I moved on.

Product Pitch:

ReadyPour is a technology that makes life a little bit easier. It a simple addition to laundry detergent containers that makes the measuring cap obsolete. Instead, the necessary amount of liquid can be poured into a washing machine directly from the container with ease. No more soap getting on the container, the machines, or your hands! It’s a simple but clever solution, and we want to see the technology adopted in all everyday laundry detergent containers. The technology is patent pending.

Product Description:

My invention is a relatively simple enhancement to liquid laundry detergent containers. While the non-spill spout from Worldwide Dispensers is helpful in reducing spills, the necessity of a cap still frustrates consumers because detergent gets on their hands, the container, the floor, etc. Additionally, detergent is wasted.

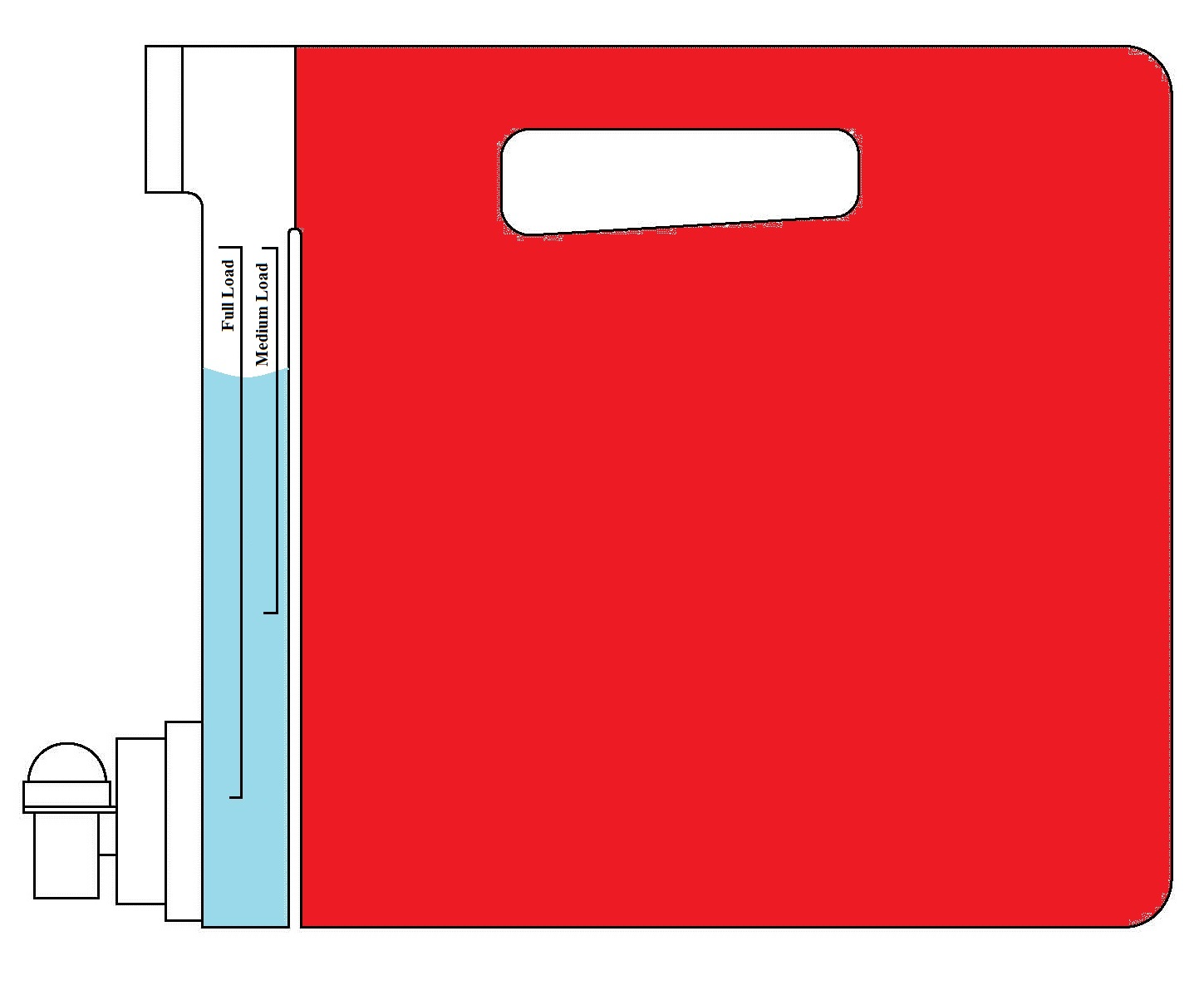

The invention is a separated partition in the container (which may be contained within the handle) that features a non-opaque measuring method whereby the user may dispense a "full" or "medium" load and such directly into a washing machine without utilizing the cap to do it (which is the norm).

The partition is filled by simply tipping the container IN the direction of the partition. The partition's reservoir is isolated form the bulk detergent when made upright. A near-optimal pressure head can be contained because the partition can be made to hold excess detergent. In a standard design, you have to tip the container when the detergent runs low. This is not the case for this invention. See attached documents for images and how to use.

Implementation costs should be largely constrained to only upfront costs. No additional "piece" is necessary to manufacture the designs, and co-molding processes are suitable for transparency for the partition.